Description

WWSE “PROFESSIONAL” WHEEL WEIGHING PLATFORMS

Platforms designed for creating weighing stations for large vehicles (vans, trucks, tankers, tractor-trailers, etc.); particularly accurate and sturdy, with attention to details

|

|

|

- Platform dimensions: 700x561mm. Height 55mm. Weight approximately 26kg.

- Loading surface: 700x450mm.

- Fitted with wheels for transporting the platform.

- Sturdy structure, made in special aluminium, which guarantees lightness and makes these suitable also for harsh working conditions.

- Cable with quick connector, platform side.

- 10 m cable for connecting platform to indicator, complete of connector.

- IP68 stainless steel load cells.

- Hermetic junction box with IP68 protection degree.

- Special vulcanised nonslip rubber applied under the platform, for good grip on all types of surfaces.

- Extremely simple and reliable connection of the scale to the weight indicator.

- The WWS platforms are patented; the number is 1.342.302.

- Availables in legal for trade approved version.

- Availables in high resolution version.

- Availables upon price estimate in Atex version for 1&21 e 2&22 zones.

|

|

|

|

NOTES ON THE CE-M APPROVED VERSIONS

|

|

|

- The platforms are for legal for trade use:

– In the single-platform systems, not used to weigh vehicles.

– In the wheel weighing systems in which the number of platforms is equal to the number of vehicle wheels.

– In the axle weighing systems composed of one or more multiples of WWS platforms, except possible limitations of use for some European States.

- The axle weighing systems with 2 WWS platforms and a 3590E “AF09” weight indicator are OIML R134 certified for the dynamic vehicle weighing, according to the legal standards in force in the Country of use.

- The CE-M legal for trade divisions indicated in the “version” table are available with ECEM option. ECEM option is needed for each legal for trade platform of the system.

- Legal for trade systems with more than one WWS, are fitted with the approval of the weight sum and related division:

Exemple for a 4 pads system

Single CE-M Platform: Max=1500kg and e=0,5kg

CE-M SUM: Max=6000kg and e=2kg

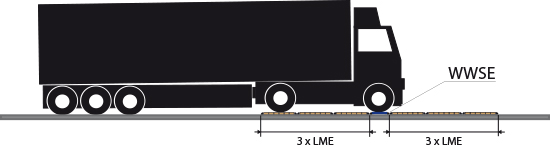

AXLE WEIGHING SYSTEM INSTALLATION: USEFUL INFORMATION

All the specifications and images can be subject to variations and upgrades without prior notice. |

NOTES: The best weighing condition is obtained by creating a levelling area of a length equal to double that of the longest vehicle to be weighed.

NOTES: The best weighing condition is obtained by creating a levelling area of a length equal to double that of the longest vehicle to be weighed.