Logistics

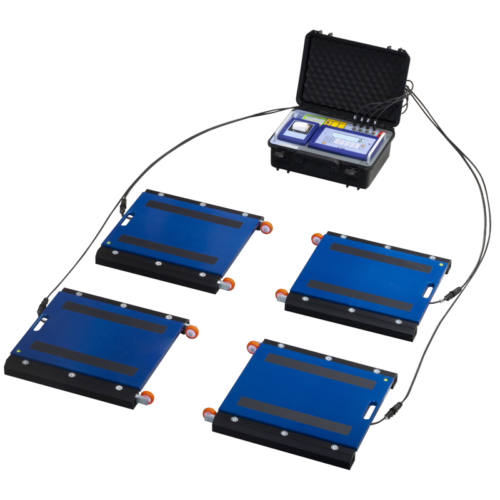

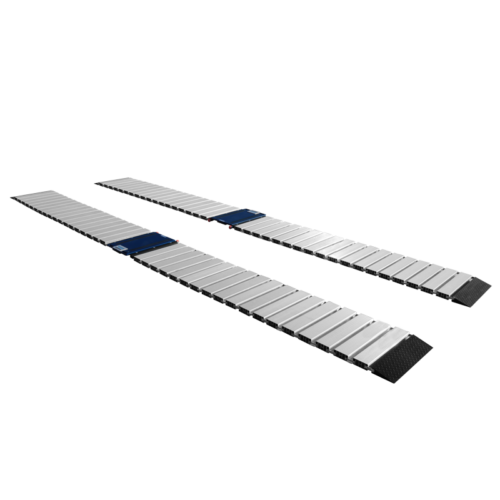

Axle Weighing

Where space or process discounts the use of a weighbridge - whether you are looking for a mobile solution, or something a little less permanent than a weighbridge but still need a trade approved solution, or better resolution than a weighbridge can offer - Axle Pads are a cost effective and highly accurate solution.

We have a lot of experience with AXLE pads in terms of what works, and most importantly - what doesn't. If you have any questions, please do not hesitate to call us.

Talk to us today on 01684 561 002

Our Axle Weighing Categories